Search Market Research Report

Zero Point Clamping System Market Size, Share Global Analysis Report, 2025 - 2034

Zero Point Clamping System Market Size, Share, Growth Analysis Report By Product Type (30 kN Retention Force, 60 kN Retention Force, 90 kN Retention Force and Others), By Application (Parts Processing, Machinery Manufacturing and Others), By Sales Channel (OEM and Aftermarket), And By Region - Global Industry Insights, Overview, Comprehensive Analysis, Trends, Statistical Research, Market Intelligence, Historical Data and Forecast 2025 - 2034

Industry Insights

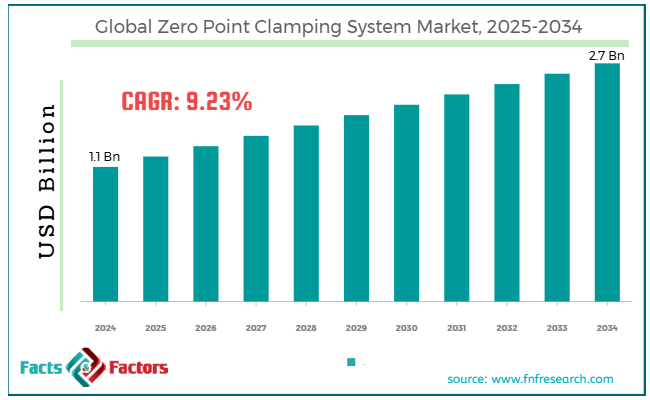

[221+ Pages Report] According to Facts & Factors, the global zero point clamping system market size was worth around USD 1.1 billion in 2024 and is predicted to grow to around USD 2.7 billion by 2034 with a compound annual growth rate (CAGR) of roughly 9.23% between 2025 and 2034.

Market Overview

Market Overview

The zero point clamping system is a special kind of positioning and locking holding system that can maintain the workpiece's zero point when moving from one machine tool to another, or from one process to another. For the exact clamping module to be interchangeable on various machine machines, a strong clamping force and repeatable positioning accuracy are needed. It is extensively utilized in many different machine tools, including turn milling compounds, horizontal and vertical machining centers, and so on. Although the layout of zero point positioning varies widely throughout businesses, the idea remains the same. Through unique mechanical structures, they all use hydraulic or pneumatic control modes to tighten or loosen the positioning pin.

Key Insights

Key Insights

- As per the analysis shared by our research analyst, the global zero point clamping system market is estimated to grow annually at a CAGR of around 9.23% over the forecast period (2025-2034).

- In terms of revenue, the global zero point clamping system market size was valued at around USD 1.1 billion in 2024 and is projected to reach USD 2.7 billion, by 2034.

- Technological advancement is expected to drive market growth over the forecast period.

- Based on the product type, the 60 kN Retention Force segment is expected to dominate the market during the forecast period.

- Based on the sales channel, the OEM segment is expected to capture the largest market share over the forecast period.

- Based on region, North America is expected to dominate the market during the forecast period.

Growth Drivers

Growth Drivers

- Numerous advantages drive market growth

Numerous advantages such as increased productivity, maximum repeatability, and increased process reliability are expected to drive the market expansion over the anticipated timeframe. The zero point clamping system significantly boosts the efficiency of procedures that need precision by automating them. Up to 90% less time is spent setting up machines, and little cleaning and upkeep is required for the system. Synergies that were before unattainable are made possible by the ability to connect operations sequentially in a single workpiece clamping system that is set up in different machining cells and has the same clamping system geometry. Throughout the whole manufacturing process, the workpiece is accompanied by the workpiece carrier equipped with the zero point clamping system, guaranteeing the highest level of accuracy and economy.

Additionally, Errors in drilling, lasering, flat or cylindrical grinding, rotating, wire or die eroding, milling, and measuring are decreased by the zero point clamping system. Additionally adding to the exceptional process reliability is the maintenance-free architecture.

Restraints

Restraints

- High investment and integration complexity hinder market growth

Zero Point Clamping Systems frequently need a large initial outlay of capital. These systems can be expensive to buy and install, particularly for small and medium-sized businesses (SMEs) with limited financial resources. In addition to the initial purchase, there can be further expenses for maintenance, integration with current manufacturing processes, and training.

Furthermore, it can be difficult to integrate zero point clamping systems with current production lines and gear. Compatibility problems could occur, especially with older technology, which could result in possible disruptions and extra expenses. Certain technological know-how is needed for these systems' installation and operation. For some businesses, manufacturers may need to invest in employing qualified technicians or training their personnel.

Opportunities

Opportunities

- Rising innovative product launches offer an attractive opportunity for market growth

The rising innovative product launch is expected to offer an attractive opportunity for market growth over the projected period. For instance, in October 2024, the ground-breaking Hilma.UC 125 machine vise, a true concentric clamp made for adaptability and efficiency in machining operations, was presented by ROEMHELD North America. Presented by STARK Spannsysteme GmbH, a proud member of the ROEMHELD Group, this creative solution promises to simplify setup for various workpieces and eliminate the need for several clamping devices for a variety of clamping applications. With just a few easy steps, this machine vise may be readily adjusted to handle a wide range of workpiece geometries, hence the moniker "Universal Clamp," or "UC," in the clamping system.

Due to its easily movable base and two parallel slides that can be adjusted with ease using an adjustment spindle, the Hilma.UC 125 achieves an extraordinary degree of flexibility. A center bearing guarantees accurate and centered alignment with amazing repeatability, and a tension spindle safely clamps workpieces while producing an astonishing 52 kN tensile force.

Challenges

Challenges

- Limited awareness and adoption pose a major challenge to market expansion

Some sectors or regions do not have a high level of awareness regarding the advantages of zero point clamping systems. The adoption rate may be slowed by this ignorance. Growth in the market may be hampered by firms who are reluctant to adapt and would rather continue using conventional clamping and workholding techniques. Thus, limited awareness and adoption pose a major challenge to market growth.

Report Scope

Report Scope

Report Attribute |

Details |

Market Size in 2024 |

USD 1.1 Billion |

Projected Market Size in 2034 |

USD 2.7 Billion |

CAGR Growth Rate |

9.23% CAGR |

Base Year |

2024 |

Forecast Years |

2025-2034 |

Key Market Players |

Zeroclamp, Piranha Clamp GmbH, EROWA, Garant, Spreitzer GmbH, LANG Technik GmbH, Romheld GmbH Friedrichshutte, Vischer & Bolli AG, Lang Werkzeugtechnik GmbH, AMF ANDREAS MAIER GmbH, F-Tool, SCHUNK, and others. |

Key Segment |

By Product Type, By Application, By Sales Channel, and Region |

Major Regions Covered |

North America, Europe, Asia Pacific, Latin America, and the Middle East &, Africa |

Purchase Options |

Request customized purchase options to meet your research needs. Explore purchase options |

Segmentation Analysis

Segmentation Analysis

The global zero point clamping system industry is segmented based on product type, application, sales channel and region.

Based on the product type, the global zero point clamping system market is bifurcated into 30 kN Retention Force, 60 kN Retention Force, 90 kN Retention Force and Others. The 60 kN Retention Force segment is expected to dominate the market during the forecast period. The segment expansion is attributed to its heavy duty application across industries. The capacity to handle big workpieces and high levels of precision are essential for industries like aerospace and automotive. Because it offers the strength and stability required for cutting large and complex components, the 60 kN retention force is perfect for these industries.

Furthermore, since they frequently work with huge, heavy parts that need accurate and secure fastening, the construction and heavy machinery manufacturing industries also profit from high-retention-force clamping systems.

Based on the application, the global zero point clamping system industry is bifurcated into parts processing, machinery manufacturing and others.

Based on the sales channel, the global Zero Point Clamping System market is segmented into OEM and Aftermarket. The OEM segment is expected to capture the largest market share over the forecast period. The need for a zero point clamping system is anticipated to increase as more businesses implement cutting-edge production technology. OEMs can increase their market share and revenue by adding these systems to their equipment offerings.

Additionally, the use of sophisticated workholding solutions is being driven by the trend towards Industry 4.0 and smart production. Manufacturers stand to gain from this trend by increasing sales and revenue when they incorporate zero point clamping systems into their smart machinery solutions. Thus, driving the segment expansion.

Regional Analysis

Regional Analysis

- North America is expected to dominate the market during the forecast period

North America is expected to dominate the market over the forecast period. Advanced clamping systems such as zero point clamping systems are becoming more and more popular due to the trend towards smart production and Industry 4.0. To increase efficiency and connection, North American manufacturers are incorporating these systems into their operations more and more.

Furthermore, the extensive usage of robotics and CNC machines in North American production demands the employment of accurate and dependable workholding systems. Zero point clamping system gives these automated systems the accuracy and stability they require. Furthermore, the zero point clamping system industry is expanding due to several government programs that stimulate the adoption of cutting-edge technology and increase manufacturing capacities. Thus, this is expected to stimulate market expansion in the region.

Competitive Analysis

Competitive Analysis

The global zero point clamping system market is dominated by players like:

- Zeroclamp

- Piranha Clamp GmbH

- EROWA

- Garant

- Spreitzer GmbH

- LANG Technik GmbH

- Romheld GmbH Friedrichshutte

- Vischer & Bolli AG

- Lang Werkzeugtechnik GmbH

- AMF ANDREAS MAIER GmbH

- F-Tool

- SCHUNK

The global zero point clamping system market is segmented as follows:

By Product Type

By Product Type

- 30 kN Retention Force

- 60 kN Retention Force

- 90 kN Retention Force

- Others

By Application

By Application

- Parts Processing

- Machinery Manufacturing

- Others

By Sales Channel

By Sales Channel

- OEM

- Aftermarket

By Region

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- Southeast Asia

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Industry Major Market Players

- Zeroclamp

- Piranha Clamp GmbH

- EROWA

- Garant

- Spreitzer GmbH

- LANG Technik GmbH

- Romheld GmbH Friedrichshutte

- Vischer & Bolli AG

- Lang Werkzeugtechnik GmbH

- AMF ANDREAS MAIER GmbH

- F-Tool

- SCHUNK

Frequently Asked Questions

Copyright © 2025 - 2026, All Rights Reserved, Facts and Factors