Search Market Research Report

Check Weigher Machine Market Size, Share Global Analysis Report, 2025 - 2034

Check Weigher Machine Market Size, Share, Growth Analysis Report By Product Type (Automatic, Semi-Automatic and Manual), By Capacity (Up to 12 kg, 12 to 60 kg and Above 60kg), By Application (Pharmaceuticals, Food and Beverages, Logistics and Packaging and Others) And By Region - Global Industry Insights, Overview, Comprehensive Analysis, Trends, Statistical Research, Market Intelligence, Historical Data and Forecast 2025 - 2034

Industry Insights

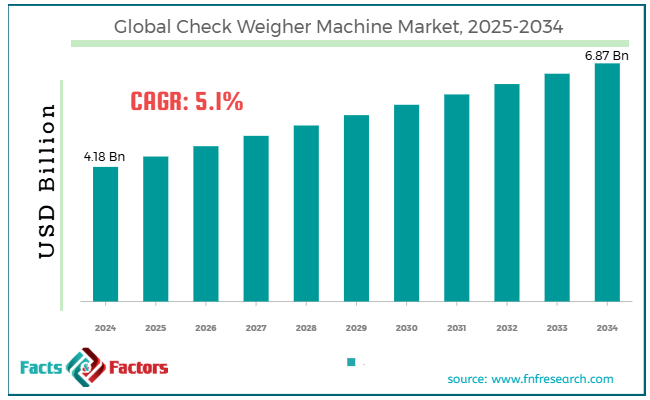

[222+ Pages Report] According to Facts & Factors, the global check weigher machine market size was worth around USD 4.18 billion in 2024 and is predicted to grow to around USD 6.87 billion by 2034 with a compound annual growth rate (CAGR) of roughly 5.1% between 2025 and 2034.

Market Overview

Market Overview

An automated or manual device for determining the weight of packaged goods is called a check weigher. It is often located after the production process and is used to make sure that a pack of the commodity weighs no more than a certain amount. Packs that exceed the tolerance are automatically removed from the line. More than 500 items can be weighed by a check weigher in a minute, depending on the size of the carton and the required precision. Checkweighers can be utilized in conjunction with metal detectors and X-ray equipment to verify and address additional features of the pack.

The market for check weigher machines market is being driven by several factors including the growing food & beverages industry, increasing exports and imports, growing demand from the pharmaceutical sector, technological advancements, growing product launches and others.

Key Insights

Key Insights

- As per the analysis shared by our research analyst, the global check weigher machine market is estimated to grow annually at a CAGR of around 5.1% over the forecast period (2025-2034).

- In terms of revenue, the global check weigher machine market size was valued at around USD 4.18 billion in 2024 and is projected to reach USD 6.87 billion, by 2034.

- The demand from several end-use industries including pharmaceutical, chemicals and others is expected to drive market growth over the forecast period.

- Based on the type, the automatic segment is expected to dominate the market over the forecast period.

- Based on the application, the pharmaceuticals segment is expected to hold the largest revenue share over the projected period.

- Based on region, North America is expected to dominate the market during the forecast period.

Growth Drivers

Growth Drivers

- Increasing demand from end-use industries drives market growth

The end-use industries, which include the food and beverage, pharmaceutical, chemical, and other sectors, are the main drivers of the need for check weighers. Check weighers are necessary for measuring a variety of goods in the pharmaceutical industry globally, such as bottles, cans, sachets, sticks, capsules, standing pouches, bags, cases, and cartons. Check weighing is being used more frequently in the pharmaceutical manufacturing industry as a result of the increasing need for accurate product weighing to abide by quality control regulations and prevent expensive fines. In the pharmaceutical sector, check weighers decrease product giveaways while increasing accuracy and dependability.

Additionally, since there is increased investment in this field, check weighers are needed more regularly since process automation is becoming more and more important in the manufacturing of pharmaceuticals.

Restraints

Restraints

- The high cost of machines hinders market growth

Check weigher machine installation and acquisition can be expensive, particularly for small and medium-sized businesses (SMEs). Some businesses may find it prohibitive to make the initial expenditure necessary for highly precise and technologically advanced devices.

Furthermore, over time, the costs of routine maintenance and operations may mount up. For check weighers to operate accurately, they need to be calibrated regularly, have their parts replaced, and have technical support. These recurring costs can be burdensome, especially for startups and smaller businesses with limited funds.

Opportunities

Opportunities

- Rising product launch provides a lucrative opportunity for market growth

The product launches are expected to offer a lucrative opportunity to market growth during the forecast period. For instance, in November 2022, A new combination solution for Track & Trace and Checkweighing, designed for small and mid-market firms in the cosmetics and pharmaceuticals industries, was introduced by Mettler-Toledo Product Inspection. With the Mettler-Toledo CT33 system, operators may achieve supply chain traceability, compliance, improved brand protection, and quality control due to a deep level of integration between Mark & Verify, serialization, and precision weighing capabilities.

Challenges

Challenges

- Technical complexity poses a major challenge to market expansion

It can be technically challenging to operate sophisticated check weigher equipment, necessitating the expertise of trained professionals for setup, use, and troubleshooting. For businesses without the required technological resources, the requirement for specific training and experience may be a hurdle.

Furthermore, it can be difficult to integrate check weigher machines with current production lines and data management systems. Compatibility problems and the requirement for specialized solutions can make deployment more difficult, resulting in delays and extra expenses. Thus, technical complexity poses a major challenge to the market growth.

Report Scope

Report Scope

Report Attribute |

Details |

Market Size in 2024 |

USD 4.18 Billion |

Projected Market Size in 2034 |

USD 6.87 Billion |

CAGR Growth Rate |

5.1% CAGR |

Base Year |

2024 |

Forecast Years |

2025-2034 |

Key Market Players |

METTLER TOLEDO, ISHIDA CO. LTD., YAMATO-Scale GmbH, DIBAL, CARDINAL SCALE, GENERAL MEASURE, THERMO FISHER SCIENTIFIC INC., VARPE, WIPOTEC-OCS GmbH, Bizerba, PRECIA MOLEN, Doran Scales Inc., IMANPACK, Hardy Process Solutions Inc., Avery Weigh-Tronix, ALL-FILL INC, Loma Systems, and others. |

Key Segment |

By Product Type, By Capacity, By Application, By End Use, and Region |

Major Regions Covered |

North America, Europe, Asia Pacific, Latin America, and the Middle East &, Africa |

Purchase Options |

Request customized purchase options to meet your research needs. Explore purchase options |

Segmentation Analysis

Segmentation Analysis

The global check weigher machine industry is segmented based on product type, capacity, application and region.

Based on the product type, the global check weigher machine market is bifurcated into automatic, semi-automatic and manual. The automatic segment is expected to dominate the market over the forecast period. The segment expansion is attributed to the growing demand for automation. Automation is being used by industries more and more to increase productivity, lower labor costs, and reduce human error. Automatic check weighers play a crucial role in automated manufacturing lines, resulting in notable increases in productivity and reliable quality control.

Furthermore, automatic check weighers may be expensive initially, but they pay for themselves over time with lower labor expenses, less product waste, and more operational efficiency. Businesses are strongly encouraged to implement these systems due to their high return on investment (ROI). Thus, this is expected to drive the market growth.

Based on the capacity, the global check weigher machine industry is bifurcated into up to 12 kg, 12 to 60 kg and above 60kg.

Based on the application, the global check weigher machine market is bifurcated into pharmaceuticals, food and beverages, logistics and packaging and others. The pharmaceuticals segment is expected to hold the largest revenue share over the projected period. The growth of the segment is attributed to the strict regulation. To guarantee the safety, effectiveness, and quality of pharmaceutical products, regulatory agencies like the European Medicines Agency (EMA) and the Food and Drug Administration (FDA) place stringent regulations on the sector. By assisting businesses in adhering to laws about precise dosage and packaging, check weighers help them steer clear of expensive recalls and legal problems.

Moreover, to guarantee proper dosages for pharmaceutical items, incredibly accurate weight measurements are necessary. High accuracy is provided by automatic check weighers, which is crucial for protecting patient safety and the integrity of pharmaceutical items.

Regional Analysis

Regional Analysis

- North America is expected to dominate the market during the forecast period

North America is expected to dominate the market during the forecast period. The market growth in the region is attributed to the presence of major pharmaceutical companies and the stringent regulation by regulatory bodies. The goal of increasing production efficiency, cutting labor costs, and minimizing errors are what motivates the use of automation technologies, such as check weigher machines. To meet market needs and improve their competitiveness,

North American manufacturers are depending more and more on automated procedures. In addition, the area is home to several top producers and pioneers of check weigher equipment. Constant improvements in data analytics, sensor technology, and integration skills lead to the adoption of increasingly complex and effective check weigher systems.

Competitive Analysis

Competitive Analysis

The global check weigher machine market is dominated by players like:

- METTLER TOLEDO

- ISHIDA CO. LTD.

- YAMATO-Scale GmbH

- DIBAL

- CARDINAL SCALE

- GENERAL MEASURE

- THERMO FISHER SCIENTIFIC INC.

- VARPE

- WIPOTEC-OCS GmbH

- Bizerba

- PRECIA MOLEN

- Doran Scales Inc.

- IMANPACK

- Hardy Process Solutions Inc.

- Avery Weigh-Tronix

- ALL-FILL INC

- Loma Systems

The global check weigher machine market is segmented as follows:

By Product Type

By Product Type

- Automatic

- Semi-Automatic

- Manual

By Capacity

By Capacity

- Up to 12 kg

- 12 to 60 kg

- Above 60kg

By Application

By Application

- Pharmaceuticals

- Food and Beverages

- Logistics and Packaging

- Others

By Regional Segment Analysis

By Regional Segment Analysis

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- Southeast Asia

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Table of Content

Industry Major Market Players

- METTLER TOLEDO

- ISHIDA CO. LTD.

- YAMATO-Scale GmbH

- DIBAL

- CARDINAL SCALE

- GENERAL MEASURE

- THERMO FISHER SCIENTIFIC INC.

- VARPE

- WIPOTEC-OCS GmbH

- Bizerba

- PRECIA MOLEN

- Doran Scales Inc.

- IMANPACK

- Hardy Process Solutions Inc.

- Avery Weigh-Tronix

- ALL-FILL INC

- Loma Systems

Copyright © 2025 - 2026, All Rights Reserved, Facts and Factors